Fuel purification and clarification machine CMM-6RL

Fuel oils are used in many industries. Fuel consumers include ships, tractors, harvesters, trucks, diesel trains, etc. Many enterprises try to purchase large batches of fuel in order to insure themselves against seasonal price fluctuations and to avoid overpaying through the use of warehouse inventory of petroleum products.

During long-term storage, not all types of fuels feature the required stability. Fuel undergoes oxidation, water ingress, and the formation of resinous substances. As a result, the fuel turns dark and loses its operational properties. Such fuel cannot be used, because it will impair the engine operation due to resinous deposits in the engine fuel supply devices, as well as soot caking on the walls of combustion chambers, exhaust valves, and nozzles, and water will render the high-pressure fuel pump inoperative. Therefore, there is a need for such fuel to be prepared/pretreated before feeding into diesel engines and power plants.

Purification of fuel

Various methods are used to purify fuel after long-term storage: settling, filtration, and centrifugation. These methods are suitable for removing mechanical impurities and water; however, they are unable to restore the original color and smell of the fuel, as well as to reduce the sulfur content. This requires using additional purification by means of special adsorbents of natural origin.

CMM-6RL machine for clarification and purification of fuel

The technology for adsorptive purification of fuel is implemented in CMM-6RL machine. The machine consists of six columns each of which is filled with an adsorbent having good absorptive properties. When passing through the columns, the adsorbent captures unsaturated and aromatic hydrocarbons, asphalt-resin substances, sulfur-, nitrogen- and acid-containing compounds from the fuel. Fuel is clarified, and regains its group composition and operational properties.

After saturation of the adsorbent, СMM-6RL machine switches to the reactivation mode. In this mode, the adsorbent properties are reclaimed after which the adsorbent is reused for purification and clarification of fuel.

What types of fuel can be purified using the CMM-6RL machine

The CMM-6RL machine cleans the following types of fuels:

- diesel fuel;

- heating oil;

- pyrolysis fuel (made of plastic and/or cellulose, not from used tires);

- or used industrial oils.

What fuel parameters are improved after processing in the CMM-6RL machine

- acid number decreasing;

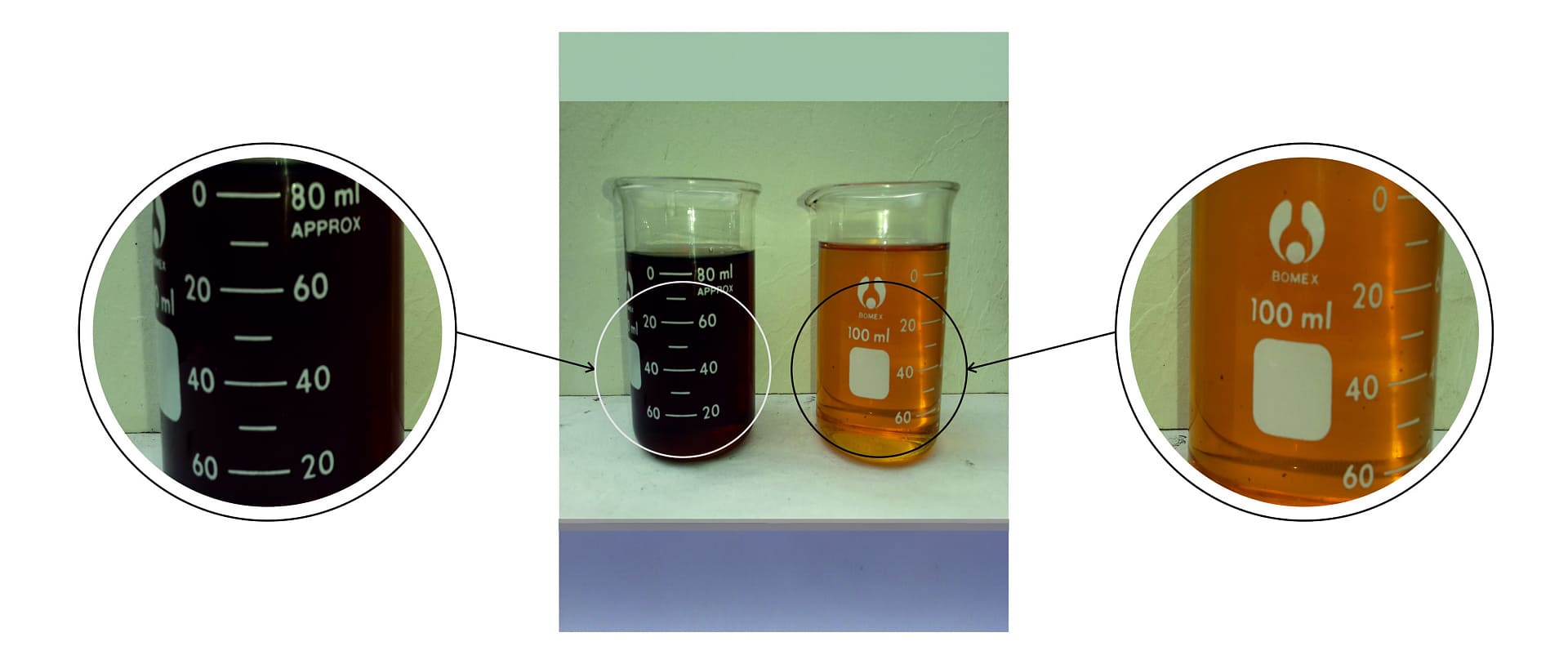

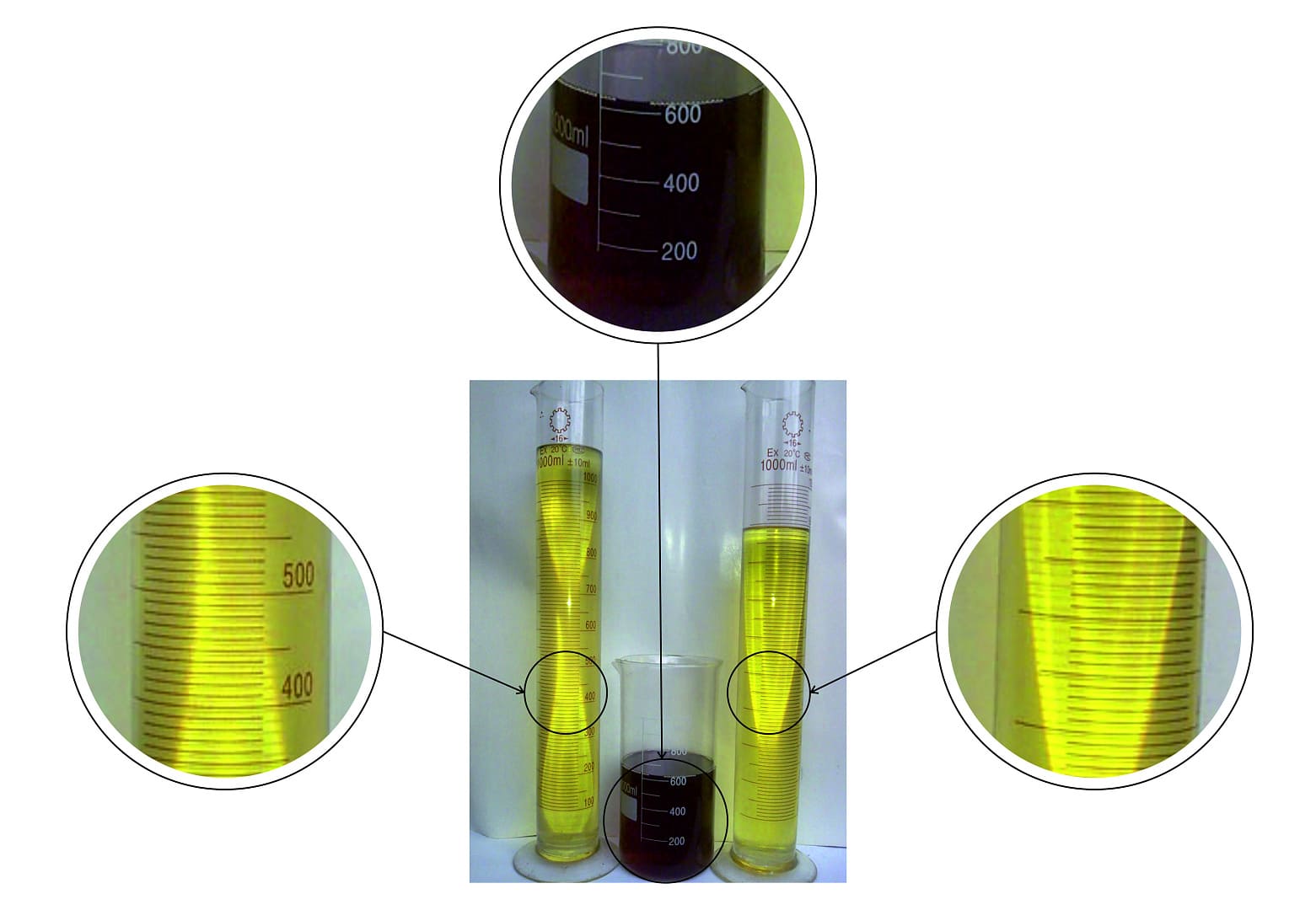

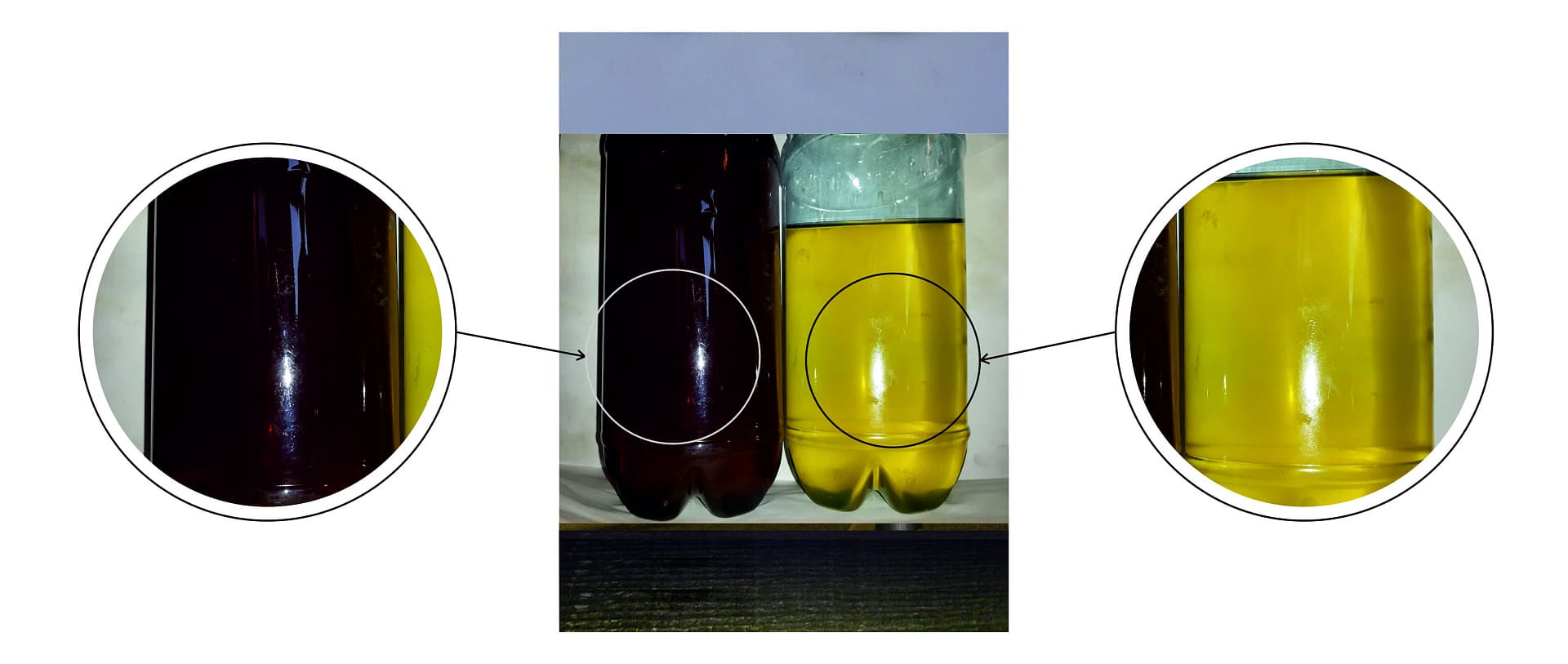

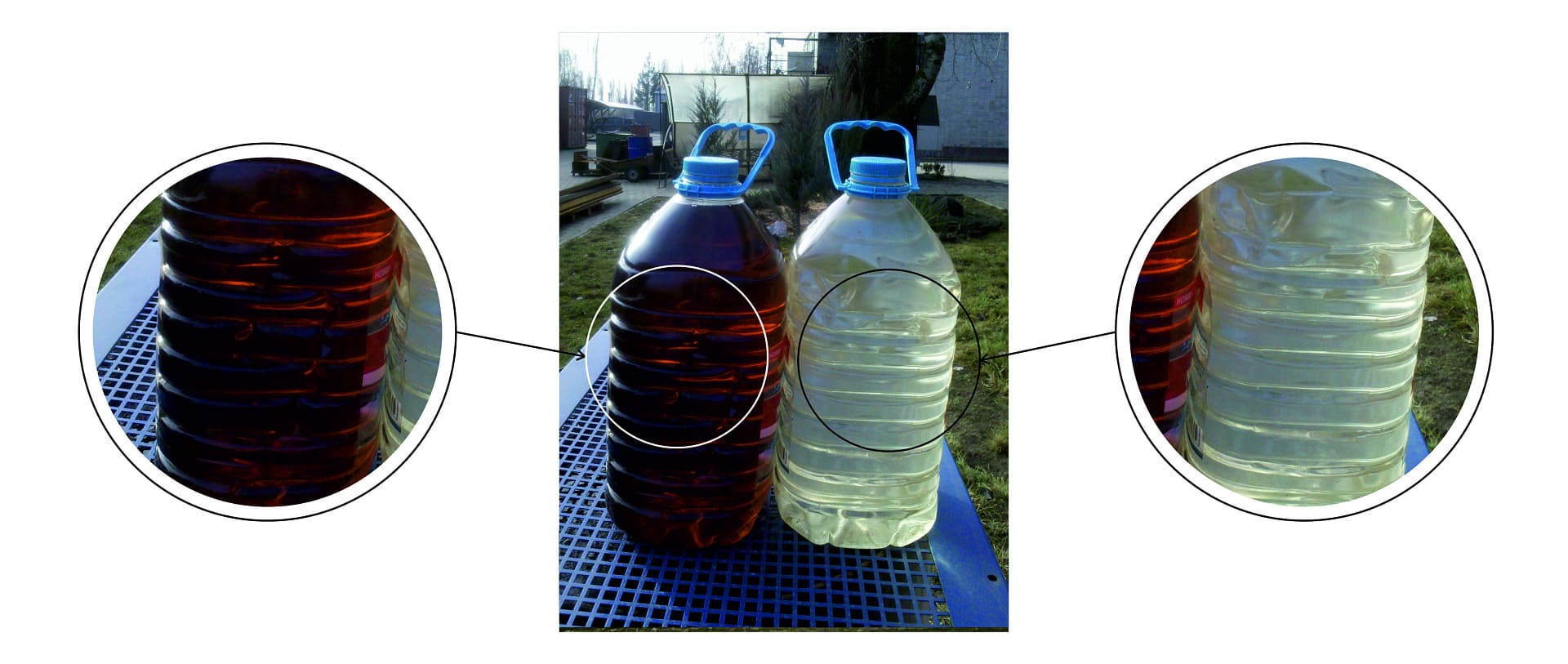

- clarification (color bleaching);

- odor removal;

- water removal (by adding to CMM-6RL an additional section of CMM-1CF with coalescing filters).

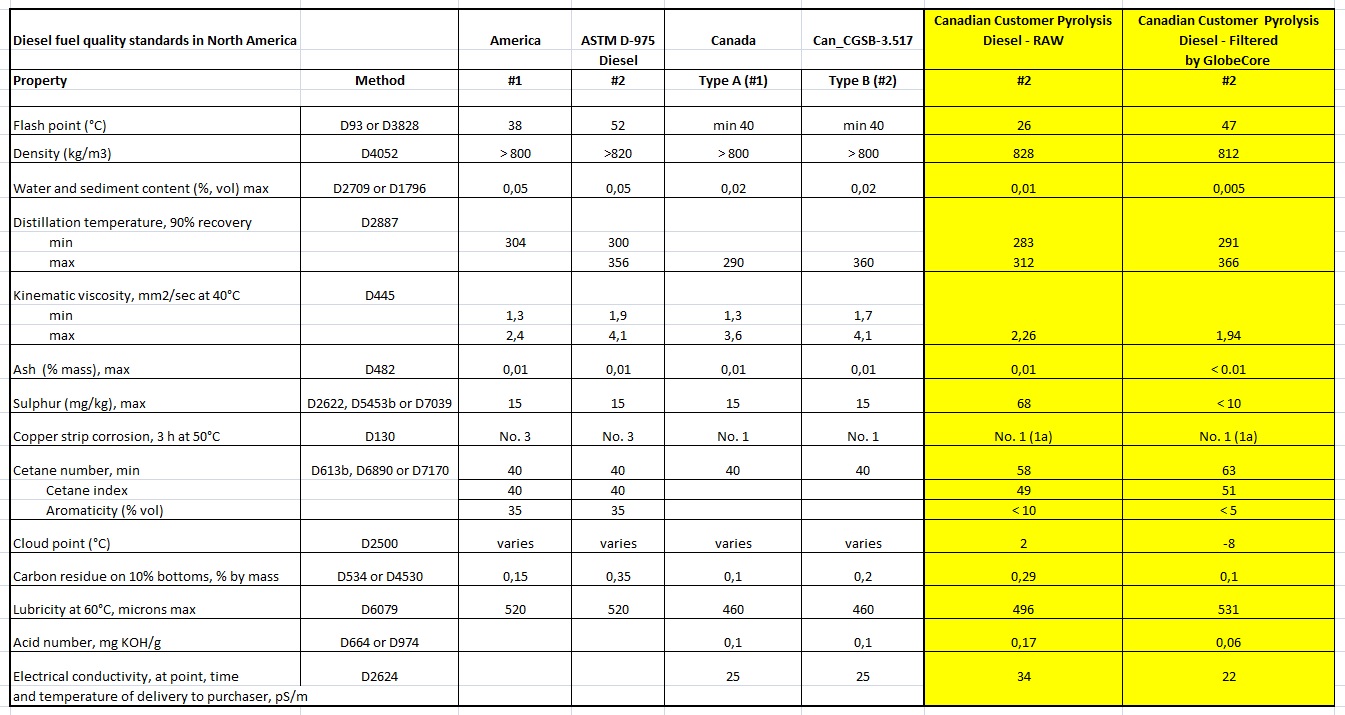

Results of the experiment on the purification of pyrolysis fuel by GlobeCore CMM-6RL machine Operation features of CMM-6RL machine for clarification and purification of fuel

Operation features of CMM-6RL machine for clarification and purification of fuel

The main feature of CMM-6RL machine is the possibility to reactivate the adsorbent without removing it from the regeneration columns which helps to process minimum 180 tons of product. If the used adsorbent should be disposed of in other equipment of a similar intended purpose, GlobeCore technology ensures reclamation of the adsorbent by burning, as well as repeated use thereof for purification and clarification of fuel (at least 300 reactivations).

Duration of operating cycles and power consumption

CMM-6RL machine for purification and clarification of diesel fuels sequentially operates in the following modes:

- Fuel purification and clarification (duration — 6 h, power consumption — 1.5 kW/h);

- Adsorbent reactivation:

- preparation (duration — 1 h, power consumption — 6.25 kW/h);

- adsorbent ignition (duration — 1 h, power consumption — 17.5 kW/h);

- adsorbent combustion (duration — 15 h, power consumption — 25.5 kW/h);

- refilling (duration — 0.5 h, power consumption — 6.5 kW/h).

Total power consumption: 57,25 kW/h.

Specification

| No. | Parameter | Value |

| 1 | Capacity, m3/h | 0.45* |

| 2 | Sorbent reactivation time, not more than | 19 hours |

| 3 | Three-phase 50, 60 Hz AC power supply voltage, V | 380/480 |

| 4 | Dimensions, mm, not more than

– length – width – height |

2820 1570 1730 |

| 5 | Weight, kg, not more than | 2100 |

* – in order to obtain the best result of fuel purification, it is recommended to first remove mechanical impurities by means of CMM-4.0F machine; and water — by means of CMM-1.0CF machine.

Advantages

- Convenience of operation. The machine is quickly connected to tanks for clean and dirty fuel through camlock quick couplings; the fuel purification process is visually monitored by means of sight glasses; a service hatch is provided at the bottom of the columns for their maintenance and cleaning.

- The machine can operate in automatic mode. The required operating mode is selected, and the actuators are controlled from the touch panel which displays a mnemonic diagram of the machine. In order to enable the control buttons, the operator just needs to touch them.

- The adsorbent is reclaimed without being removed from the machine and can be used for the next regeneration cycle immediately after cooling. At the end of the last reactivation, the adsorbent can be used as a construction aggregate or in agriculture to loosen compact soils.

- There occur no harmful emissions into the environment during the machine operation. The machine is equipped with a two-stage system for neutralization of combustion products which consists of a carbon filter and a catalytic converter.

Practical results

Diesel fuel

Heating oil

Pyrolysis fuel

Low-viscosity marine fuel oil