Oil Regeneration Machine CMM-6RL

Industrial oils are a large group of commercial oils that comprises several classes:

- transformer oil;

- hydraulic oil;

- turbine oil.

These classes are united by a common function – lubrication of friction components of various industrial equipment and operation in harsh conditions characterized by high temperatures, voltage and pressures, as well as by hydrodynamic and marginal friction modes.

During operation, when affected by harmful factors, industrial oils become contaminated with water, mechanical impurities, and sludge; aging of oils occurs and their acid number increases. The use of aged industrial oils leads to equipment breakdowns and costly repairs. These consequences are prevented by timely change of industrial oil. After flushing, new oil is poured into the system, and the old one is sent for disposal.

Regeneration of industrial oils in CMM-6RL machine

GlobeCore’s experience indicates that the useful life of most industrial oils is not fully expired at the time of change, since they contain useful hydrocarbons. If harmful impurities and aging products are removed from oil by regeneration, it will completely regain its properties and can be reused in industrial equipment.

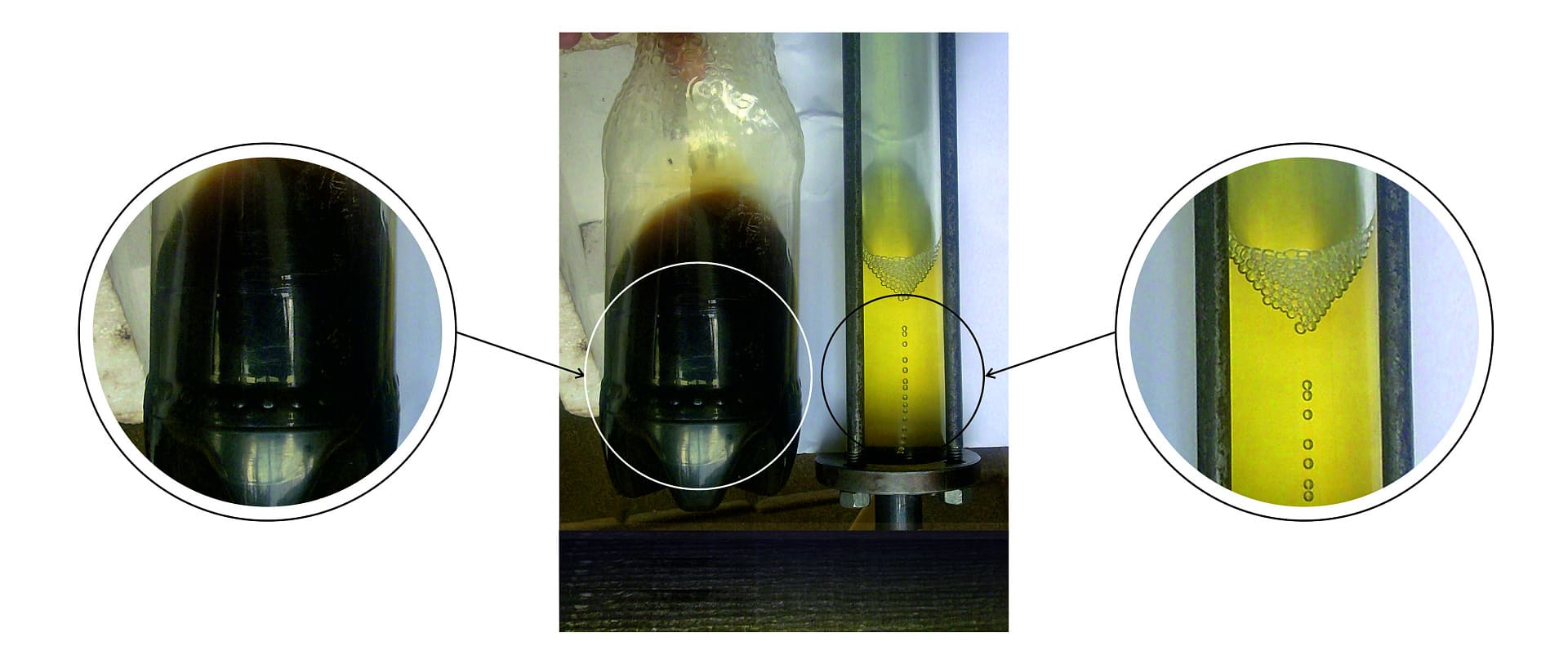

GlobeCore technique for regeneration of industrial oils implemented in CMM-6RL machines is based on pumping the oil through a layer of natural adsorbent. The adsorbent is placed into the regeneration columns, and when the oil passes through the adsorbent, it absorbs and retains all aging products, including acidic constituents. At the same time, the structure of useful hydrocarbons remains unchanged. At the machine outlet, regenerated industrial oil has the performance close to that of new industrial oil; thus, it can be reused for its intended purpose.

Results of transformer oil regeneration by GlobeCore CMM-6RL machine

| # |

Parameter |

Before reclamation |

After reclamation |

Norm |

Norm according to IEC 60296 |

| 1 | Appearance |

Dull, dark brown |

Clear, transparent |

– |

Clean, free of sediment and suspended solids |

| 2 | Acid number, mg KOH per 1 g of oil , not more than |

0.63 |

0.01 |

0.01-0.05* |

0.01 |

| 3 | Sulfur corrosion |

Presence |

Lack of |

– |

Lack of |

| 4 | Moisture content ppm, no more than |

170 |

5 |

– |

30-40 |

| 5 | Breakdown voltage, kV, more than |

11 |

73 |

30-55** |

30-70 |

| 6 | Dissipation factor at 90°C/194°F, %, not more |

4.0 |

0.001 |

0.5 |

0.005 |

| 7 | Gas content, % |

12 |

0,1 |

– |

– |

| 8 | Surface tension at 25°C/77°F , mN/m |

22 |

45 |

– |

40 |

| 9 | The size of mechanical impurities, um |

50 |

0.2 |

Lack of |

Lack of |

| 10 | Oxidation stability:- Acid number, mg KOH per 1 g of oil , not more than |

– |

0.2 |

0.15-0.35 |

1.2 |

* – Depending on the type of oil

Operation features of CMM-6RL machine for regeneration of industrial oil

The main feature of CMM-6RL machine is the possibility to reactivate the adsorbent without removing it from the regeneration columns. If the used adsorbent should be disposed of in other equipment of a similar intended purpose, GlobeCore technology ensures reclamation of the adsorbent by burning, as well as repeated use thereof for regeneration of industrial oil (at least 300 reactivations).

Duration of operating cycles and power consumption

CMM-6RL machine for regeneration of industrial oils sequentially operates in the following modes:

- Oil regeneration (duration — 6 h, power consumption — 1.5 kW/h);

- Adsorbent reactivation:

- preparation (duration — 1 h, power consumption — 6.25 kW/h);

- adsorbent ignition (duration — 1 h, power consumption — 17.5 kW/h);

- adsorbent combustion (duration — 15 h, power consumption — 25.5 kW/h);

- refilling (duration — 0.5 h, power consumption — 6.5 kW/h).

Total power consumption: 57,25 kW/h.

Specification

| No. |

Parameter |

Value |

| 1 | Capacity, m3/h |

0.45* |

| 2 | Sorbent reactivation time, not more than |

19 hours |

| 3 | Three-phase 50, 60 Hz AC power supply voltage, V |

380 |

| 4 | Dimensions, mm, not more than

– length – width – height |

2820 1570 1730 |

| 5 | Weight, kg, not more than |

2100 |

* – in order to obtain the best result of industrial oil regeneration, it is recommended to first remove mechanical impurities by means of CMM-4.0F machine and water – by means of CMM-1.0CF machine.

Advantages

- Convenience of operation. The machine is quickly connected to tanks for clean and dirty oil through camlock quick couplings; the oil purification process is visually monitored by means of sight glasses; a service hatch is provided at the bottom of the columns for their maintenance and cleaning.

- The machine can operate in automatic mode. The required operating mode is selected, and the actuators are controlled from the touch panel which displays a mnemonic diagram of the machine. In order to enable the control buttons, the operator just needs to touch them.

- The adsorbent is reclaimed without being removed from the machine and can be used for the next regeneration cycle immediately after cooling. At the end of the last reactivation, the adsorbent can be used as a construction aggregate or in agriculture to loosen compact soils.

- There occur no harmful emissions into the environment during the machine operation. The machine is equipped with a two-stage system for neutralization of combustion products which consists of a carbon filter and a catalytic converter.

Practical results

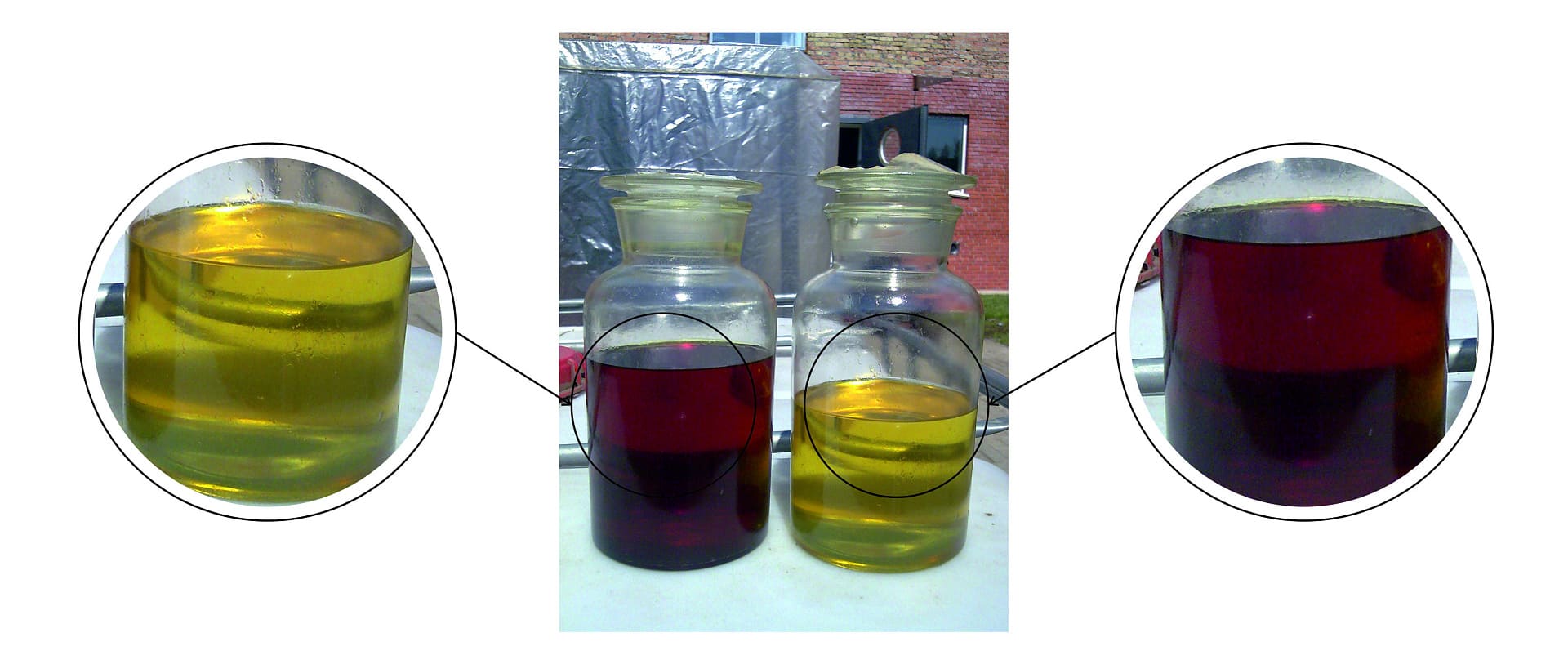

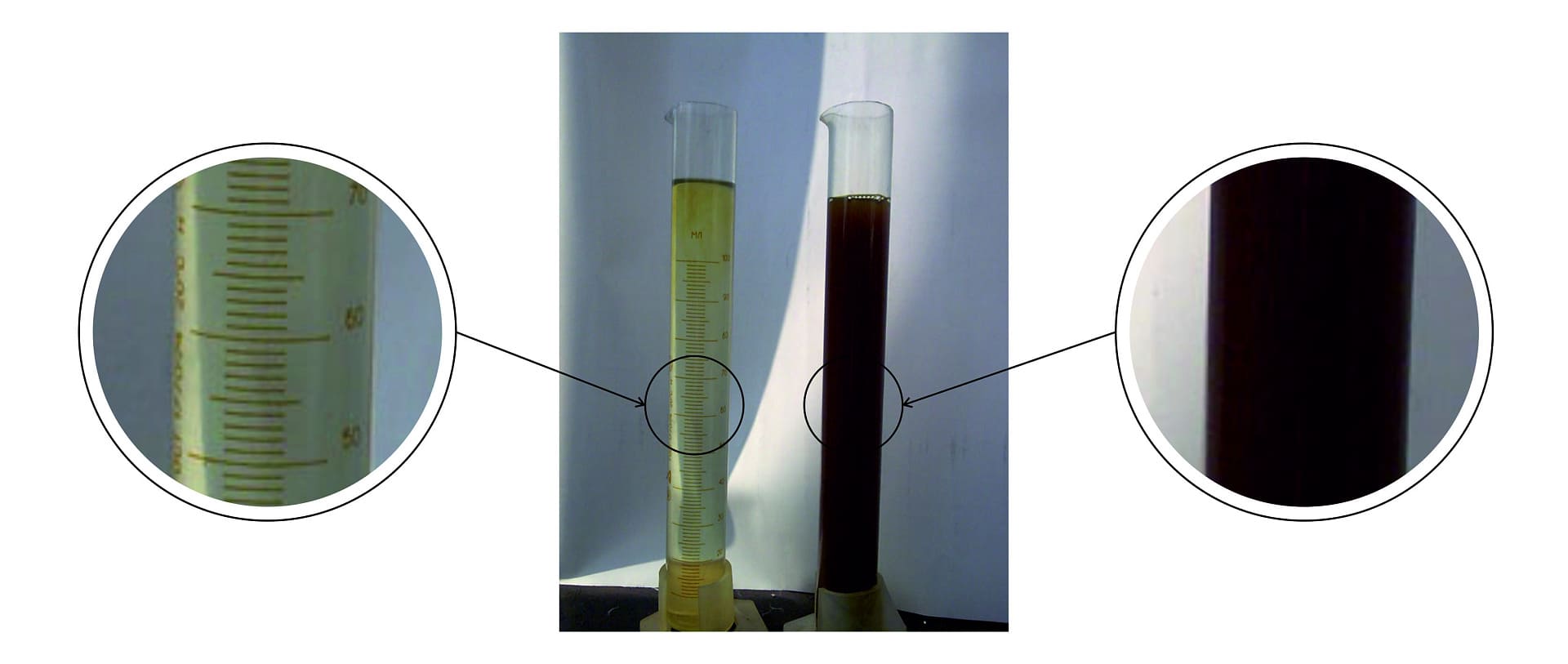

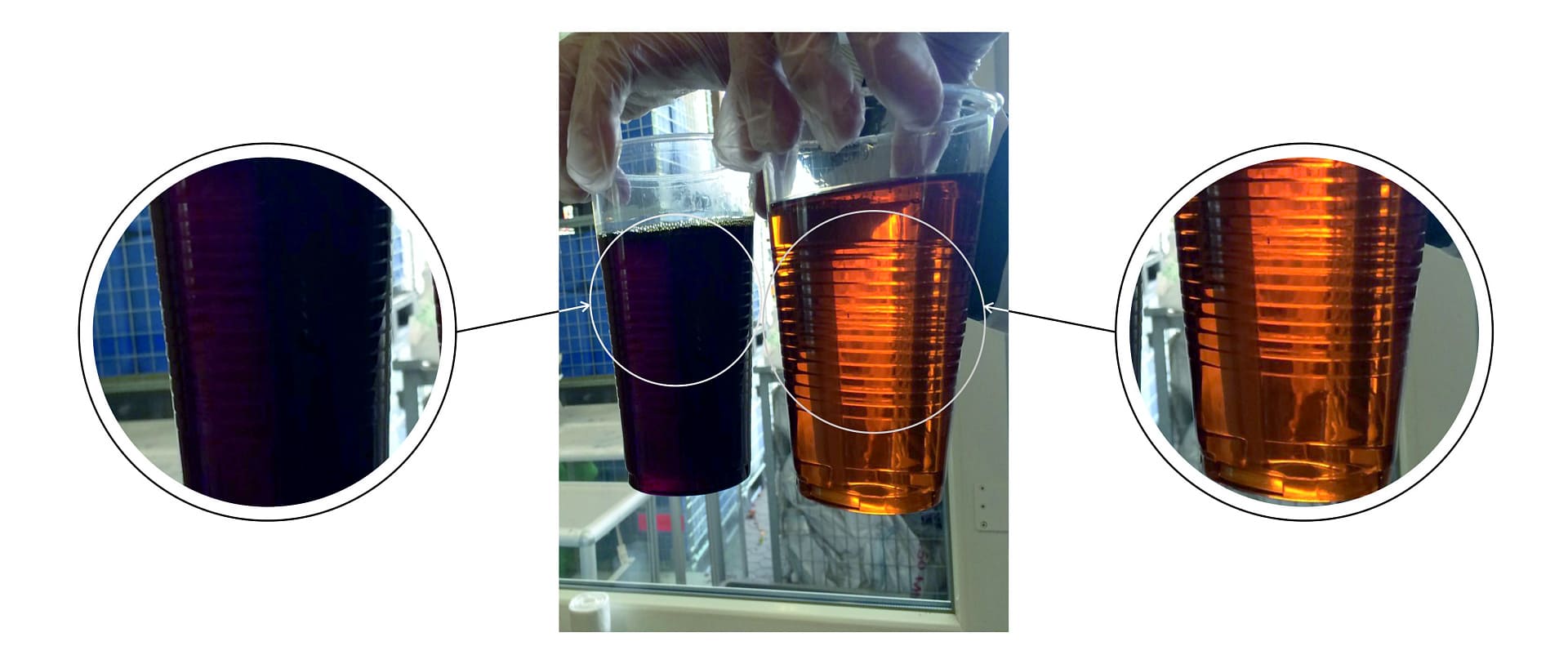

Transformer oil

Turbine oil

Industrial oil

Motor oil