First, we must understand what the term “used oil” means. We suggest using the definition given by the United States Environmental Protection Agency (EPA). It says that, “used oil is any oil that has been obtained from crude or synthetic oil that has been in use and as a result was contaminated by physical and chemical impurities.”

When servicing commercial and equipment, oil is often mixed with dirt, water, metallic parts and chemical substances, and as a result, it can no longer perform its functions efficiently. To resume the normal operation of the equipment, oil should be changed or regenerated.

According to the regulations of EPA, oil should comply with three criteria:

(1) Origin. Used oil is refined from crude oil, coal, oil shale or other material, based on polymers. Animal and vegetable oils therefore, do not belong in the “used oils” catagory.

(2) Application. One should know where used oils may be applied. Used oil includes lubricating oils, heat-transfer fluids, coolants, insulating oil, solutions for copper and aluminum wire rolling, and gearbox fluids. This list is non-exclusive and only provides an incomplete list of industries where used oils may be applied.

(3) Contaminants. Oil is considered to be used only if it is contaminated as a result of practical use. Physical contaminants include metal chips, filings, and dirt. Such substances as solvents, halogens or mineralized water are also considered to be chemical impurities.

Used Oil Disposal

Oil that is no longer able to perform its functions should be disposed of or recycled. According to worldwide estimates, about 1.5 billion liters of used oil is being disposed of annually.

In general, a recycled product is used by the same industry sector, but sometimes it may be applied in quite a different sector of industry. For example, reclaimed motor oil may be either sold in the auto shops or used as residual fuel oil. Solutions for aluminum wire rolling that are supposed to be reused, are being restored directly on-site.

There are several ways to recycle used oil such as follows:

(1) On-site recycling. Such a method extends the service life of oil though does not provide for complete oil restoration.

(2) Recycling at oil refineries. In such a case, used oil serves as raw material or coker when producing petrol or coke.

(3) Reclamation. In the course of this process, all impurities are being removed so that oil can continue to be used in the present or the future. In theoretical terms, due to reclamation, oil may serve you forever.

(4) Used oil is burned for energy recovery. In this case, water and impurities are removed to a level that allows for the oil to be burned. This method is less preferred since oil may be recycled only once.

The following facts favor the reclamation/regneration process:

(1) Reduced energy resources. Reclamation technologies require three times less of the energy needed to process crude oil to lubricating oil.

(2) 67.2 liters of crude oil are needed to get 1 liter of fresh oil, when only 1.6 liter of used oil is required to get the same amount of fresh oil.

Used Oil Applications

The following is the list of institutions that deal with used oils:

(1) Service stations, while servicing vehicles and different industrial equipment;

(2) Used oil collection centers that accept, stores and aggregate used oil;

(3) Used oil transporters that deliver used oil to the used oil collection centers; Used oil transfer facilities are institutions that store oil for more than one day and up to 35 days.

(4) Oil refineries;

(5) Used oil burners; and

(6) Used oil fuel marketers.

As mentioned above, reclamation is considered to be the most effective method of used oil recycling. It will be reasonable and cost effective for the companies that deal with huge amounts of oil products to buy their own oil reclamation equipment. It allows the companies to reduce energy costs, hazardous waste and transportation costs.

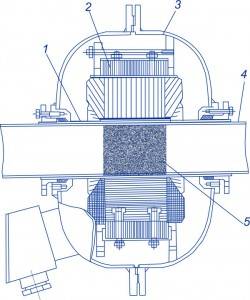

GlobeCore has produced universal equipment, designed for regeneration of transformer oil, industrial oil, turbine oil, transmission fluids and other types of oil. There is no need to change the design of the units when switching to a different type of oil or fluid for processing.

Due to advanced GlobeCore regeneration technology, used oil is being restored to its original new like condition, thereby contributing to environment and energy resources preservation.