The one of the most used petrochemical products on production facilities is industrial oil and different types of this oil. Industrial oil is the most available and reliable for liquid insulation, for cooling and electrical protection for power transformers, turbines, hydraulic equipments etc.

Industrial oil has a lot of advantages which include long lifetime (without adding of antioxidizing additives – from 3 to 10 years); continuous working and protection of industrial systems. So the question concerning using other type of oil arises not frequently. Other advantage of industrial oil is reasonable price; also this oil is not so aggressive for environmental, industrial oil not produce the burned gas or other wastes which pollute the atmosphere.

Industrial oil has a lot of advantages which include long lifetime (without adding of antioxidizing additives – from 3 to 10 years); continuous working and protection of industrial systems. So the question concerning using other type of oil arises not frequently. Other advantage of industrial oil is reasonable price; also this oil is not so aggressive for environmental, industrial oil not produce the burned gas or other wastes which pollute the atmosphere.

Industrial oil has only one problem – utilization after usage. It is the problem which is the most discussed in our days. The main questions are decline of pollution charges, complete refill of used oil inside of engines and systems, reduction of the expenses for buying, shipping, preparation and maintenance of new oil etc.

The modern solution for all these problems concerning refilling of used industrial oil is usage of complex systems for oil filtration, degassing, re-refining and regeneration which are use different adsorbtion components.

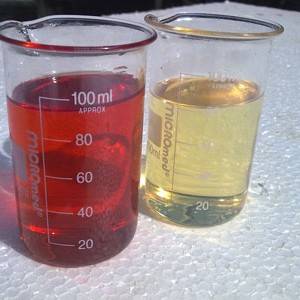

Industrial oil before and after regeneration.

It was investigated that the most effective result can be obtained when during one purification cycle the unit restores all characteristics of the oil and also exists the possibility of recirculation of all components of purification system, including adsorbing agents.

Fuller’s earth is very popular and most used component for industrial oil regeneration (oil recycling) all over the world.

Fuller’s earth is highly active bleaching clay with pronouncedsorption properties. This earth is famous also by its mineral composition. Fuller’s earth consists of hydrated aluminium silicates which contain metal ions (magnesium, natrium and calcium).

Montmorillonite is the principal clay mineral from which is composed Fuller’s earth. The presence and ratio of other minerals such as kaolinite, attapulgite and palygorskite depends from the changes in chemical composition. This component looks like clay but it has fine structure, higher water content and has no natural clayey plastic property. By means of it adsorbing agent Fuller’s earth retains the moisture.

The deposits of this type of clay were found all over the world. The main Fuller’s earth deposits are located in United Kingdom, Japan and USA.

Fuller’s earth is wide used in industrial branches and in medicine and cosmetology.

For oil regeneration this component is irreplaceable. Fuller’s Earth is used for purification of mineral and vegetable oils and greases.

The latest technologies in oil regeneration allow using all properties of Fuller’s earth in complex systems.

On our new units for transformer oil regeneration we use the system which allows restore all oil characteristics (by using Fuller’s earth) and at the same time exhausted clay can be also regenerated in the same unit.

Designed equipment for oil regeneration with the Fuller’s earth as an adsorbing agent corresponds to all ecological and technological trends and standards. This type of units for oil restoration filled another gap in the market of direct and alternative usage of mineral products.

Engineers from GlobeCore company have designed different equipment for mineral oils regeneration (transformer oil, industrial oil, turbine oil, diesel oil, heating oil, diesel fuel, gas condensate, kerosene etc). On this website you can find a lot of interesting information concerning oil recycling and oil regeneration

How many tons of used oil recycling machine are disposed every year? How many damages we bring to our environmental? Stop throw out your profit into wastes, start recycling and you will obtain the benefits.

How many tons of used oil recycling machine are disposed every year? How many damages we bring to our environmental? Stop throw out your profit into wastes, start recycling and you will obtain the benefits.