We discuss Electroplating Wastewater Treatment in this article.

At the beginning of the twenty first century, the urgency of solving the issues of global environmental problems significantly increased. Today, humanity has almost come to the point where further ignoring of the need to preserve the Earth’s ecosystem will be very costly for future generations. There are many global environmental problems and each of them deserves attention. This article will discuss the protection of the hydrosphere from all forms of pollution.

As a result of human activities, industrial wastewater is constantly being generated all over the world. The draining of industrial wastewater into open waters without the proper treatment can lead to irreparable consequences for the environment. The situation becomes more complicated each day by the fact that industries are developing rapidly and the amount of wastewater increases proportionally to the increases in the size and scope of modern human industries.

According to the World Health Organization (WHO), human diseases caused by the consumption of contaminated water and food can be as high as 80% of the total number of health problems reported each year. Treatment of industrial wastewaters therefore, is one of the most urgent and priority tasks faced by modern man.

General Characteristics of the Electroplating Industry

The Electroplating Industry got its name from an electrochemical method of applying mechanical and chemical coatings on various materials to impart hardness and wear resistance as well as anti-corrosion protection and protective-decorative properties.

The electroplating industry can perform galvanizing, chemical passivation of stainless steel, anodizing of aluminum, chemical oxidation of aluminum and steel. The generation of wastewater is due to the need for washing parts in the process of preparation and applying the electroplate coatings.

Composition of Wastewater Generated from Electroplating Facilities

The composition of wastewater generated from the electroplating industry typically includes washing waters (diluted effluents) and concentrated solutions (pickling, washing, degreasing, chrom- and cyano-containing electrolytes).

The greatest damage to the environment is made by metal compounds that are washed out in wastewater from the electroplating industry. For example, cyano-containing effluents contain free sodium cyanide (potassium), complex cyanide salt of zinc, cadmium, copper and other metals, as well as salts of alkali and alkaline earth metals. The concentration of cyanide can range between 5 and 300 mg/l with an acidity level that exceeds the “7” mark.

Wastewater from Electroplating facilities using chromium contain hexavalent and trivalent chromium, ions of metal, copper, nickel, zinc and sulfuric acid.

Cadmium compounds, even in relatively small quantities, have a dramatic negative impact on fish and other inhabitants of fresh and saltwater resources. Other negative effects of heavy metals are also well-studied. They can enter the human body through food and water and can cause the pathogenesis of liver disease, heart disease, brain cancers, and even tumors.

Existing Methods of Treating Wastewater from Electroplating

The main objective of galvanic wastewater production treatment is to reduce the content of heavy metals to the maximum allowable concentrations. This allows you either to dump purified water into a sewer system, or return it back to use in production.

Since electroplating effluents contain a wide range of heavy metals, each of which requires a different disposition, you will have to resort to a multi-step treatment plan. Dissolved heavy metal ions must be converted into insoluble chemical compounds, followed by separating and dewatering solids. In general, the purification process consists of the following stages:

- Neutralization – A process that is necessary for the chemical disposition of metals. It comprises of setting the pH level to a certain value using sodium and calcium hydroxides;

- Flocculation – formation of macro floccules by the addition of organic flocculants;

- Precipitation – separation of the solid phase. At this stage sludge is also de-watered; and

- Polishing filtration by means of ion exchange or sorption.

Despite of all the achievements, ion exchange, reagent and coagulation methods do not fully address the issue of effective and economic efficient cleaning. Besides this, when using these methods of wastewater treatment for removing heavy metal ions, a so-called galvanic slime is formed. These substances can not be placed in landfill sites designed for solid wastes. Burial of galvanic slime requires the use of special landfills. The number special landfills is very small. Most businesses generating galvanic slime materials therefore, have to store such waste on its own property by creating temporary sludge storage areas.

Ion-exchange and reagent purification methods, using conventional equipment, are very time-consuming. The reagents are costly, have a greater metal content, and are characterized by the need for expensive and cumbersome equipment.

Use of Vortex Layer Devices in the Process of Purifying

Wastewater Generated by Electroplating Facilities

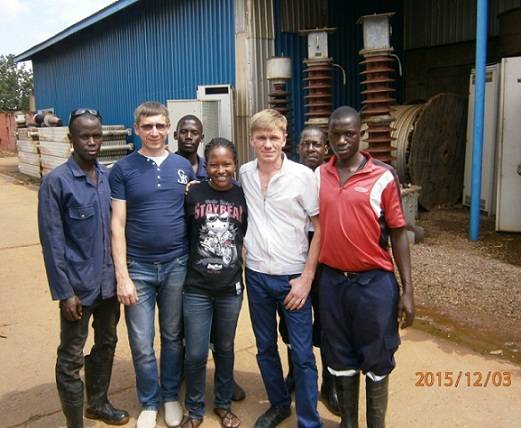

Given the aforementioned, it can be argued that the search for new and more effective approaches to the problem of wastewater treatment in the electroplating industry is highly relevant. GlobeCore manufactures a modern and effective vortex layer devices. Today, in a variety of industries there are many successful production lines equipped with such GlobeCore devices.

When analyzing the intensifying factors that occur in a vortex layer device, it can be assumed that the process of wastewater treatment will be subjected to a significant impact from:

- electrochemical factors, electromagnetic treatment, and activation of substances in the vortex layer;

- phase dispersing; and

- geometrical parameters of the operational mode of the vortex layer, and its hydrodynamic factors that provide intensive mixing of the processed media.

We have carried out studies on electroplating wastewater treatment that remove heavy metals using a GlobeCore AVS-100 type (laboratory) vortex layer device. As the reducing agent, we used sulfuric acid iron FeSO4. Recovery of the trivalent and hexavalent chromium at the expense of the reagent was carried out in an alkaline medium for which milk of lime Ca(OH)2 was introduced into the water.

Because the alkaline medium of iron hydroxide additionally acts as a reducing agent, there is no need for acidification drains. The 0.5 liters of water intended for cleaning had a 10 mg of 10% solution of ferrous sulphate added to it.

For treatment included the use of ferromagnetic particles with a length of 20 mm and a diameter of 1.8 mm with a total weight of 200 grams. The treatment time made lasted three seconds.

Table 1 below shows the results of the electroplating wastewater treatment process that removed heavy metals using a GlobeCore Magnetic Mill AVS-100 vortex layer device. The table also contains comparison data obtained with reference values and concentration limits valid for the countries of the European Union.

Table 1

Results of the Electroplating Wastewater Treatment Process Removing Heavy Metals Using a GlobeCore AVS-100 Magnetic Mill

|

No

|

Parameter name

|

Parameter value

|

Maximum allowable concentration (European Union)

|

|

before treatment

|

after treatment

|

| 1 |

рН |

1.75 |

6.74 |

6.5-8.5 |

| 2 |

Fe, mg/l |

9.7 |

2.77 |

2-20 |

| 3 |

Cu, mg/l |

18.29 |

0.65 |

0.1-4 |

| 4 |

Ni, mg/l |

5.8 |

<0.02 (not found) |

0.5-3 |

| 5 |

Cr+6, mg/l |

19.08 |

<0.005 (not found) |

0.1-0.5 |

The following conclusions can be made about Electroplating Wastewater Treatment:

1) Use of the GlobeCore AVS-100 type vortex layer device in the process of electroplating wastewater treatment will effectively reduce the concentration of heavy metals to values not exceeding the maximum permissible concentrations in the European Union. The results showed a complete absence of nickel and hexavalent chromium in the treated water. This shows that the use of the vortex layer devices in countries where there are more stringent requirements for concentrations of hexavalent chromium and nickel will be very popular.

2) Purification of water is instantaneous and does not require the overuse of reagents.

3) The process of sediment settling is achieved much faster than when using agitators.

Here at GlobeCore, we have carried out studies on the possibility of grinding coal to a pulverized state using the GlobeCore

Here at GlobeCore, we have carried out studies on the possibility of grinding coal to a pulverized state using the GlobeCore