A CMM-4 Unit Commissioned in Liberia

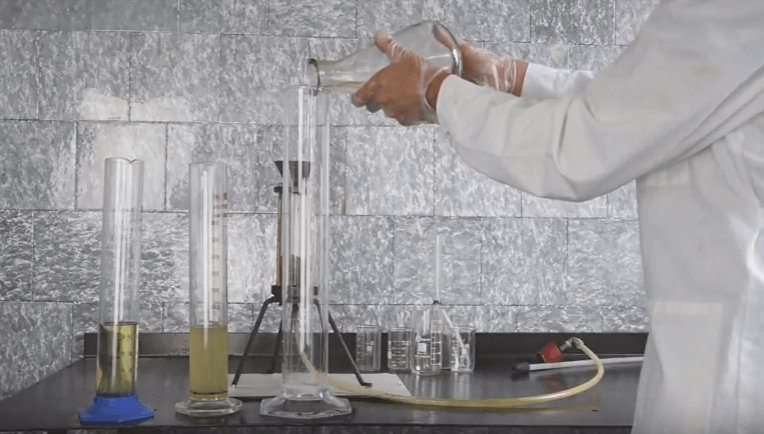

A CMM-4 Unit Commissioned in Liberia In the middle of August this year, representatives of GlobeCore visited Liveria, where they commissioned a CMM-4 unit. The commissioning process included operator training. The unit is installed on a trailer for easy transportation to the location of serviced transformers. The unit was first started at one of the local hydropower plants. Trials included operationRead More

The New CMM-1CF for Purification of Oil with Very High Water Content

The New CMM-1CF for Purification of Oil with Very High Water Content GlobeCore has successfully completed the final trials of the CMM-1CF unit with the processing rate of 1 m3/hour in May. The primary mission of this product is not only filtration, but also removal of water from industrial oil. The unit can process oil with water content of 50% and more. The CMM-1CF can process dieselRead More

GlobeCore has organized and conducted a seminar in the USA

GlobeCore has organized and conducted a seminar in the USA March 2-3, 2018 in Houston, GlobeCore held a seminar for representatives of the Texas electric power industry. During the seminar were discussed the issues of aging processes in electrical insulating oils influencing the efficiency of power transformers, including a report on the topic “Purification and regeneration of transformer oils with GlobeCore equipment”. The practical partRead More

Presentation of GlobeCore equipment in Oldenburg

Presentation of GlobeCore equipment in Oldenburg March 5, 2018 a regular presentation of oil purification and regeneration equipment was held in the International Training Center of GlobeCore (Oldenburg, Germany). This time the event was attended by representatives from Bosnia and Herzegovina, and their partners from Qatar. First of all, the guests were interested in the possibilities of GlobeCore equipment for processingRead More

Participation in IEEE PES T&D Conference & Exposition

Participation in IEEE PES T&D Conference & Exposition The 2018 IEEE PES Transmission & Distribution Conference & Exposition isn’t just the industry’s signature show — it’s an all-encompassing, immersive and global conference experience like no other. Here you’ll join top utility CEOs and some of the world’s brightest engineers in discovering the latest T&D products, ideas and innovations leading the industry forward toRead More

Participation in AWEA Wind power conference and exhibition

Participation in AWEA Wind power conference and exhibition Professionals from all over the world attend to network, learn, advance their organizational mission and to participate in the largest wind energy exhibition in the Western Hemisphere. More major product announcements and exciting releases happen here, than at any other wind energy industry event. http://www.windpowerexpo.org GlobeCore and GC Technologies will also have a booth inRead More

GlobeCore invites to the seminar in Texas

GlobeCore invites to the seminar in Texas In our constant effort to provide a superior product with exceptional service, we are pleased to announce the opening of our new sales office and service center, complete with technicians and inventory, in the USA. Our new dealer, Dave Wilson, with GC Technologies, at 1110 Paige St, Houston, Texas 77003, 713-699-3388, [email protected], 713-202-7983 (cell) isRead More

Colombia hosted an international exhibition Feria Internacional del Sector Eléctrico 2017

Colombia hosted an international exhibition Feria Internacional del Sector Eléctrico 2017 The exhibition Feria Internacional del Sector Eléctrico was established in 2006 and every two years brings together representatives of the electrical industry of Latin America and guests from other countries. This year GlobeCore took advantage of the opportunity and took part in this event, which was held in Medellin (Colombia). From November 29 to DecemberRead More

GlobeCore Opens a New Service Center in Costa-Rica

GlobeCore Opens a New Service Center in Costa-Rica Dear friends! We are happy to announce that a new service center commenced operations in Costa-Rica in November 2017. This service center will assist our clients throughout the Latin America. A stock of spare parts will be made available to the clients. It is also possible to visit the new service center to purify andRead More

СММ-2,2 project was executed in Italy

СММ-2,2 project was executed in Italy September 17, GlobeCore started up and tested a CMM-2.2 unit in Foligno (Umbria), Italy. This time, the startup and commissioning were carried out on site of a large locomotive manufacturer in Italy. Italian railers use silicone oil in their locomotive transformers. The oil mostly consists of silicon atoms, its name comes from Latin “silicium” (silicon).Read More

Transformer Tap Changers

Transformer Tap Changers Power transformers convert one voltage to another without changing frequency. The main parameter of transformer is transformation ratio, i.e. the ratio between primary and secondary coil voltages or the number of turns in the windings. To change transformation ratio, a tap changer is used, which changes the number of turns engaged at a given moment.Read More

Spain. CMM-2R transformer oil regeneration plant was commissioned

Spain. CMM-2R transformer oil regeneration plant was commissioned August 16, 2017 in Seville (Spain) all works under the contract for the supply and commissioning of the regeneration plant CMM-2R were successfully completed. This equipment is ideal for enterprises and organizations of the electric power industry, that do not require insulating oil processing capacity more than 0.3 m3 / h. The plant’s components areRead More

Commissioning in Saudi Arabia

Commissioning in Saudi Arabia August 5 – 8, 2017, in Jizan, our company engineering team carried out the commissioning and start up of the CMM-2,2 unit. This unit added to the list of equipment already provided and commissioned for the electricity industry of Saudi Arabia by GlobeCore. The CMM-2,2 unit operates is several modes, and can be used forRead More

We invite you to participate in the seminar on industrial oils purification and regeneration

We invite you to participate in the seminar on industrial oils purification and regeneration GlobeCore GmbH invites specialists of the power industry and everyone interested in innovations in electrical power industry to take part in our seminar on “Purification and regeneration of industrial oils”. The event will take place in Oldenburg (Germany) on September 27 at Edewechter Landstrasse, 173. The program of the seminar covers the problems of industrialRead More

SILICONE OIL RECYCLING UNIT CMM-1.0

SILICONE OIL RECYCLING UNIT CMM-1.0 We are all used to associating power transformers with transformer oil. But in the modern world, electrical companies widely utilize silicone oil as an alternative to mineral based fluids. This is not surprising, considering silicone oil benefits and advantages: Silicone Fluid (or Polydimethylsiloxane silicone oil) features: higher dielectric strength and temperature stability, low toxicity, lowRead More

Zimbabwe. Annual presentations of GlobeCore equipment

Zimbabwe. Annual presentations of GlobeCore equipment June 8, this year a number of presentations on GlobeCore equipment was held in Bulawayo (Zimbabwe). It was only last year in August that similar presentations were held in the capital of Zimbabwe- Harare. Then, not all the representatives from Zimbabwe electrical industry could be present at the presentations. This called for a new opportunityRead More

Equipment commissioning in Finland

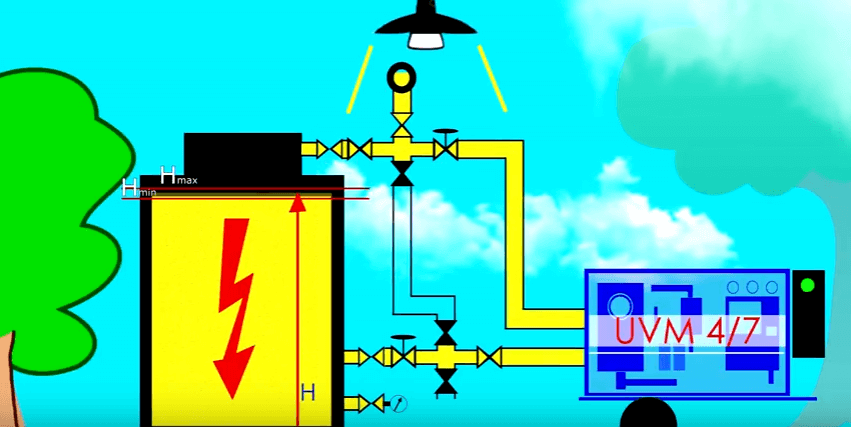

Equipment commissioning in Finland May 31, our company technical team completed the works under the contract on production, delivery and commissioning of a CMM-4/7 unit in Finland (Helsinki). This equipment is designed for businesses that repair and install high-voltage oil-filled equipment. The first transformer it services was a 400 MVA transformer. Operating modes of the unit CMM-4/7 operates inRead More

Botswana. Commissioning of CMM-12R and CMM-4/7

Botswana. Commissioning of CMM-12R and CMM-4/7 In May, more of GlobeCore equipment was commissioned in Gaborone (Botswana). At this time two transformer oil regeneration plants CMM-12R and CMM-4/7 were installed and commissioned In its design, CMM-12R is a multifunctional complex that carries out both processing of insulating oils and maintenance of transformers. The main distinguishing feature of this equipment is –Read More

The number of GlobeCore equipment is growing in Pakistan

The number of GlobeCore equipment is growing in Pakistan May 13, 2017, the number of GlobeCore equipment in Pakistan increased by one unit. A CMM-4/7 unit was commissioned by the company’s engineering team in Lahore. This equipment performs heating of power transformers, as well as drying, cleaning, degassing and nitriding of insulating oil. CMM-4/7 provides: volumetric gas content below 0.1%; moisture content by weightRead More

ELECTRICAL TRANSFORMER REPAIRELECTRICAL TRANSFORMER THE GLOBECORE PROCESS TO MAINTAIN ELECTRICAL TRANSFORMER OIL IN GOOD CONDITION Problem #1: Moisture in transformer oil Nature of Problem: Transformer oil readily absorbs moisture from the air. This water decreases dielectric strength of the oil GlobeCore Solution: CMM Oil Purification Plant is designed for thermo-vacuum drying, filtration and removal of solid impuritiesRead More

ELECTRICAL TRANSFORMER REPAIRELECTRICAL TRANSFORMER THE GLOBECORE PROCESS TO MAINTAIN ELECTRICAL TRANSFORMER OIL IN GOOD CONDITION Nature of Problem: Transformer oil readily absorbs moisture from the air. This water decreases dielectric strength of the oil GlobeCore Solution: CMM Oil Purification Plant is designed for thermo-vacuum drying, filtration and removal of solid impurities from dielectric insulating oils with aRead More

GlobeCore presented a seminar In Quito

GlobeCore presented a seminar In Quito During 2 days, May 3-4 in Quito (Ecuador), GlobeCore held a seminar presenting its equipment The event was attended by representatives of the electricity industry from many countries, including Peru, Bolivia, Argentina, Colombia, Costa Rica and El Salvador. The seminar covered the following questions: General information about GlobeCore; Modern technologies in cleaning and regeneration ofRead More

GC equipment put into operation in Saudi Arabia

GC equipment put into operation in Saudi Arabia April 23 – 27, 2017 in Jeddah (Saudi Arabia), GlobeCore engineers carried out an effective commissioning of the CMM-0,6 unit. This equipment is ideal for organizations that has oil-filled equipment and require their insulating oil cleaned from mechanical impurities, water and gases with processing rate 158 gal / h. The CMM-0,6 unit circulates the oilRead More

Putting equipment into operation in Estonia

Putting equipment into operation in Estonia April 10, 2017 GlobeCore engineers visited Tallinn (Estonia), where they prepared to start CMM-4/7 unit on the trailer. CMM-4/7 units are in demand at enterprises engaged in installation, repair and operation of power transformers, as well as other oil-filled equipment. This unit solves several tasks at once: it heats and vacuum treats a transformer, itRead More

Purification, clarification and regeneration of mineral oils and diesel fuel by the UVR-450/16 unit

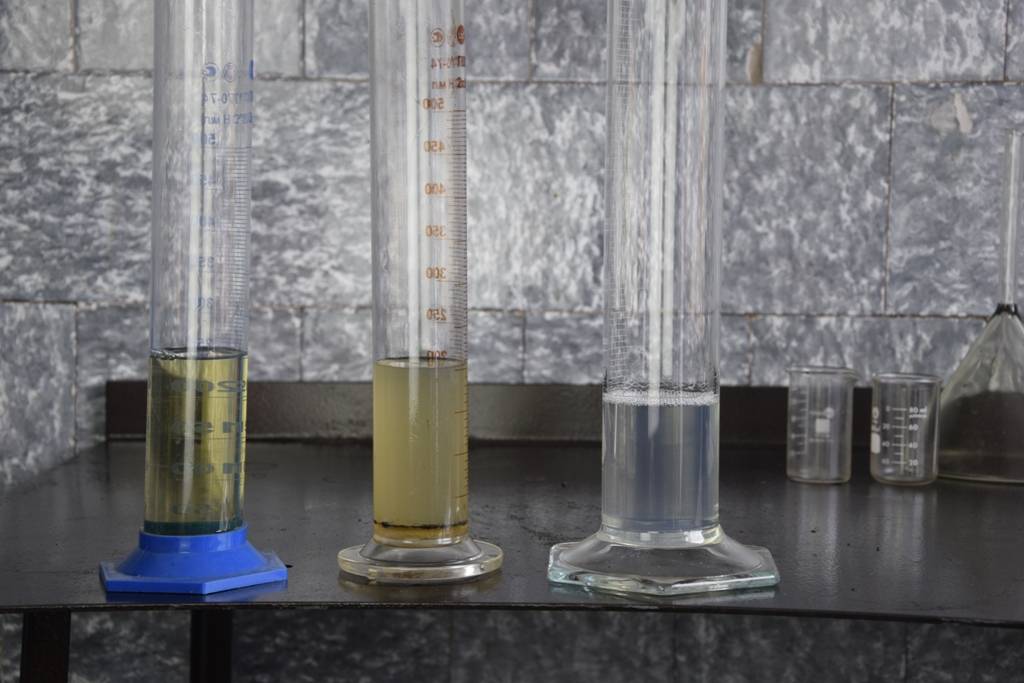

Purification, clarification and regeneration of mineral oils and diesel fuel by the UVR-450/16 unit Mineral oils. Industrial oil, turbine oil, transformer oil and compressor oils are used in difficult conditions of high temperatures, exposure to air, mechanical contamination, contamination with water etc. Over time, these oils lose their performance properties and need to be replaced or regenerated. As for other petroleum products, for example, diesel fuel may lose itsRead More

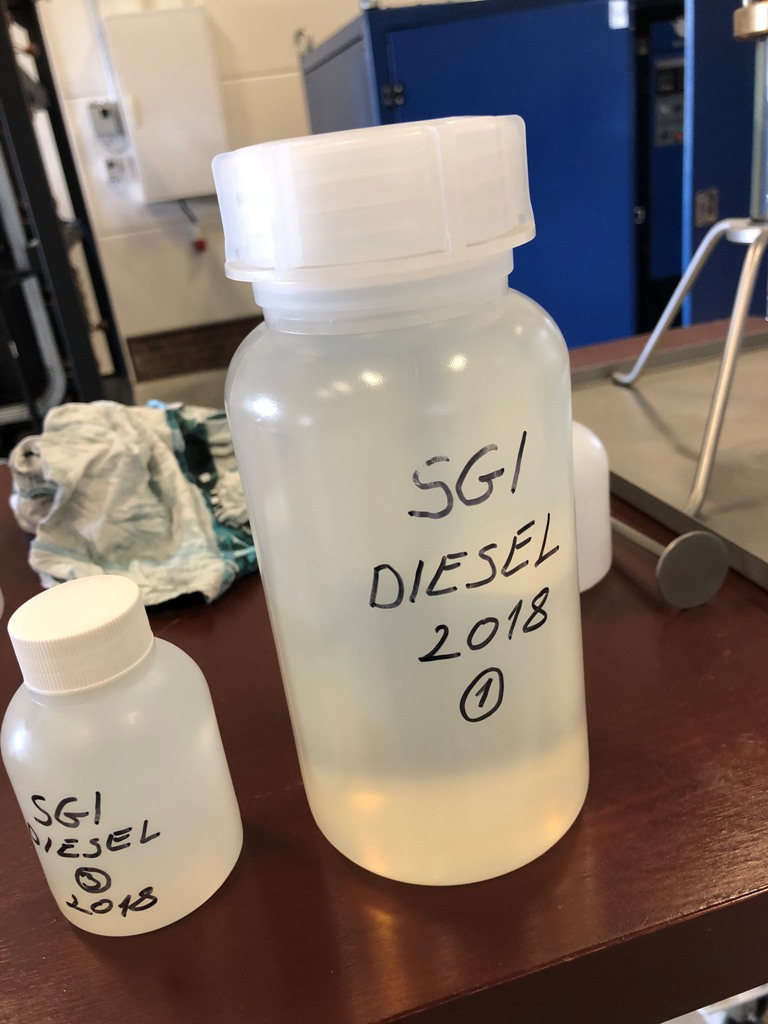

Desulfurization of diesel fuelDesulfurization of diesel fuel. Thus, the consumer receives fuel with strictly limited sulfur content. Obviously, the less sulfur, the more expensive the product. A way to save on the fuel bill is to take lower grade diesel fuel and process it to satisfy the requirements of the vehicle fleet. GlobeCore offers the desulfurization process basedRead More

GlobeCore Diesel Fuel Desulfurization UnitDiesel Fuel Desulfurization. Sulfur is a common component in crude oil, where it can be present both in elementary form and in the form hydrogen sulfide and organic substances, such as disulfides, mercaptan etc. Generally, the influence of sulfur and its compounds on oil products is negative, due to its corrosive properties. That is whyRead More

Heavy Fuel Oil: Considerations on Use

Heavy Fuel Oil: Considerations on Use Winter brings the need to heat buildings. Natural gas and diesel fuel are relatively expensive to use as heat sources, so people more and more look at alternatives. This is a good time to discuss heavy fuel oil. The main advantage of this product is ease of storage and transportation. Heavy fuel oil is madeRead More

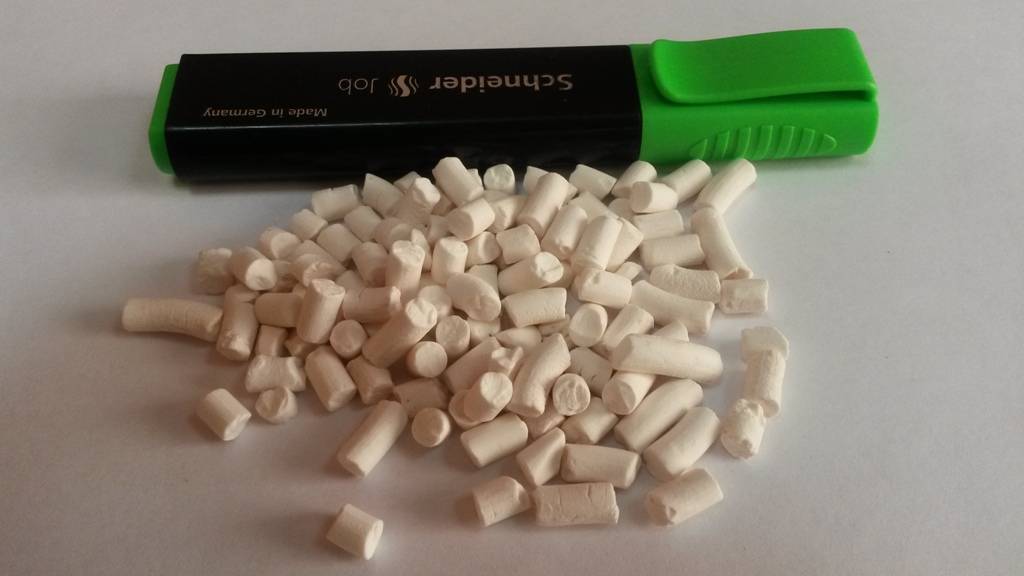

How many cubic meters of oil can be regenerated with one load of sorbent in the UVR-0.1?

How many cubic meters of oil can be regenerated with one load of sorbent in the UVR-0.1? When using the UVR-0.1 oil cleaning and regeneration unit, the most frequent questions are the average amount of sorbent used and the amount of oil processed by this sorbent. The UVR units for cleaning and regeneration of oil use a combination of thermal vacuum filtration with a special sorbent The main feature of this equipmentRead More

UVR: the best solution to the problem of fuel and oil regenerationThe question of oil regeneration generally arises after the oil has been severely polluted and changed its chemical composition as a result of long-term operation or storage. Even ordinary dust or micro organisms can significantly reduce the quality of diesel fuel; and metal shavings in industrial oil can cause failure of expensive equipment. What shouldRead More

GlobeCore becomes a member of the American Wind Energy Association (AWEA)

GlobeCore becomes a member of the American Wind Energy Association (AWEA) GlobeCore priorities are green and environmentally friendly products. This can be achieved by reusing the waste products and implementing the green energy sources. The contribution of GlobeCore technologies is made in purification of industrial oil, and by increasing the reliability of alternative power generation. We are pleased to announce that GlobeCore has become a memberRead More

CMM-4/7 degassing unit commissioned in Canada

CMM-4/7 degassing unit commissioned in Canada GlobeCore is now a member of the American Wind Energy Association (AWEA), aiming to solve urgent problems in the industry. The main objective is to increase reliability of wind turbine transformers and extend their service life. Wind turbine transformers are step-up transformers converting voltage for the power grid. They are positioned within the tower orRead More

Waste Oil Application

Waste Oil Application Today, the problem of waste oil is quite acute and requires effective methods and approaches to its solution. To understand the full extent of the problem, it is enough to look at only one fact: the amount of waste oil drained into water bodies and soil significantly exceeds the amount of the same substances enteringRead More

How to Improve Diesel Fuel

How to Improve Diesel Fuel None of the literature on diesel fuel disproves the benefits of filtration. This process helps to get rid of dust and dirt particles that can penetrate into supply system through nozzles. It is caused by periodic opening and closing of the fuel tank. When channels and spray nozzle holes are clogged, insufficient amount of fuelRead More

CMM-0.6 Launched in Italy

CMM-0.6 Launched in Italy October 5, 2016: the GlobeCore employees once again launched new equipment. This time, the commissioning of the CMM-0.6 mobile oil treatment unit took place in Carpenedolo (province of Brescia, Italy). This equipment removes mechanical impurities from transformer oil and drys it under vacuum. The input oil should have a viscosity below 70 cSt at 50Read More

Transformer oil regeneration unit UVR-L (laboratory)

Transformer oil regeneration unit UVR-L (laboratory) The UVR-L laboratory regeneration unit is designed to purify fuels and regenerate oils with viscosity below 70 cSt at 20ºС. This equipment is very versatile, capable to treat practically any type of oil products including transformer, industrial and turbine oils, as well as fuel oils, gas condensate and diesel fuels. The laboratory version of thisRead More

Diesel fuel filtersThe main purpose of the filter is to purify diesel fuel by removing contaminants which may enter oil products (dust, water, loose particles of construction materials. A fuel filter is a must in any vehicle to protect the fuel system and the motor. The below article looks into the kinds of filters available for dieselRead More

Purification of diesel fuel: filtration, separation and sorbentsDiesel fuel is a widespread oil product, so its use is always in the spot light. According to regulations, diesel fuel must not contain particles larger than 5 micron and water. Particulate matter may enter the fuel in the process of transportation and storage. Water enters the fuel most often due to its contact withRead More

GlobeCore Turbine Oil Purification Process in action

GlobeCore Turbine Oil Purification Process in action Turbine oils are used in turbine adjustment system, which is composed of oil pressure units, alignment servos, rotor servos, pivots and bearings. Contamination of oil with sludge and moisture promotes electrolytic erosion of bearings, degrades reliability of regulation system and shaft seals, causes wear of chocks and bushings, causing increased maintenance expenses, reduces performance andRead More

GlobeCore Oil Degassing Unit CMM-4/7 and a BV. Commissioning at El-Kuwait cityOn 11-12 June 2016 a СMM-4/7 and a BV vacuum section were commissioned at one of Kuwait transformer substations (El-Kuwait city). Commissioning of several units at the same time is a frequent occurrence in power industry and is very efficient. In this case, several important problems are solved. The CMM 4/7 vacuumizes transformers and purifiesRead More

New Service Center Opens in Houston

New Service Center Opens in Houston Dear friends! We are proud to annouce that the new US service center is open. Now customer support and equipment maintenance are even more accessible and prompt. You are welcome to visit us at: 1750-H Dickinson Ave (FM 1266) Dickinson, TX, 77539. Addresses of other representative offices are available in the Contacts page.

Diesel Fuel Purification: Review of Existing Methods

Diesel Fuel Purification: Review of Existing Methods The task of diesel fuel purification arises at the stage of its production, when it is necessary to get rid of water and solid impurities. Upon completion of the production process, the risk of contamination pursues diesel fuel from the refinery to the storage containers of the equipment in which it is applied. Water hasRead More

Advantages And Disadvantages of Diesel FuelDiesel fuel as well as other fuels is not ideal, therefore, it has both its advantages and disadvantages. Before you buy one petroleum product or another, getting to know with its string and weak points is a good idea. This will help you make the fullest use of its advantages and reduce the effects ofRead More

Diesel And Heating Fuel: Is There Any Difference?Very often people do not distinguish between the terms “diesel fuel” and “heating fuel”, considering them to be identical. But is it really so? Let’s try to understand. We offer three criteria for comparison: consumer, economic and industrial. In terms of consumption, there is a fundamental difference between heating fuel and diesel fuel. Heating oilRead More

Sorbent for Diesel Fuel: How to Make the Right Choice?

Sorbent for Diesel Fuel: How to Make the Right Choice? In practice, diesel fuel purification takes two consistently implemented steps: adsorption and regeneration of spent sorbent. The effectiveness of adsorption process is determined by operating characteristics of the processed sorbent. Let us consider a detailed list of substances that are used when working with diesel fuel. Activated charcoal. Activated charcoal is a non-polar substance. TheRead More

Removal of Sulfur from Diesel FuelProbably all vehicle owners heard at least once in their life that sulfur has a negative impact on diesel fuel. But if you ask what exactly is this impact, not all of them will know the answer. So, why is sulfur so harmful? First of all, it promotes fuel oxidation causing environmental pollution with exhaustRead More

Diesel Heating OilThe main industry where heating oil is used is heating services. This oil product is most often operated in stationary steam boilers and industrial furnaces. Typically, heating oil is burned in low-capacity residential heating systems. It also can be used in heat generators of average capacity operated in agriculture for the purpose of drying grain,Read More

Diesel fuel filter selectionFuel purity is one of the most important factors in reliable and prices operation of various counters and flow meters, fuelling systems, engines etc. During transportation and storage, diesel fuel may accumulate various contaminants: solid particles, paraffin, water, rust. These can damage fuel systems causing serious failures. Modern fuel lines are equipped with special filters,Read More

GlobeCore presented its equipment in Zimbabwe

GlobeCore presented its equipment in Zimbabwe GlobeCore specialists regularly participate and organize seminars and presentations in various countries. August 10-12, GlobeCore’s technical support manager Frank May visited Harare (Zimbabwe), where he made a presentation of GlobeCore equipment. During the presentation on the reasons for deterioration of insulating oil and the failures of the power transformers, GlobeCore showed its oil purification andRead More

Diesel fuel purification and equipmentContamination of diesel fuel by solid particles or water is most often the effect of long storage in tanks, transportation and pumping. In some cases, oil products can be contaminated by microbes. To evaluate the presence of, for example, water in the fuel, imagine how the engine will look after running on abrasive mixture suppliedRead More

Low visocsity marine fuel: main requirements and clarificationMarine dribbling fuel is used in ships equipped with high-speed diesel engines. This oil product consists of sour and vacuum distillates, as well as secondary products (light catalytic and thermal cracking gasoil). The following are the requirements to such fuel: cetane number above 40; sulfur content below 1.5%; iodine number below 20. Marine dribbling fuelRead More

Brand-new, Compact and Highly Effective – CMM-0.6 Oil Treatment UnitThe company GlobeCore is known for its equipment – for cleaning and regeneration of transformer oils: Most of the equipment we produce is designed for stationary use and processing oil in large quantities: We have units that are specifically designed for stationary use – near a transformer. But many of our customers have a needRead More

Oil Reclamation on ENERGIZED Transformer. Transformer Safety System

Oil Reclamation on ENERGIZED Transformer. Transformer Safety System This is an operating transformer We now need the degasser and the transformer safety system, TSS The TSS transformer safety system is a stand alone assembly, controlling the level of oil in the transformer by a pressure sensor, which is installed on the transformer using transformer ports The system is equipped with a control cabinetRead More

Reagent cleaning of diesel fuel using AVS 150 vortex-layer device and UVR fuel, oil cleaning system

Reagent cleaning of diesel fuel using AVS 150 vortex-layer device and UVR fuel, oil cleaning system GlobeCore engineers have developed a new system for desulphurization of diesel fuel and here, we will show you – how to reduce the sulfur content in diesel fuel – using purification reagents Flow chart of cleaning diesel fuel of sulfur consists of a tank with a volume of 1m3, a pump for pumping fuel fromRead More

Practical training on purification of diesel fuel In OldenburgJune 30 and July 1 the US representatives took part in a practical training on cleaning diesel fuel in Oldenburg. The training took place in the Oldenburg International Training Center that prepares specialists to operate oil purification and regeneration equipment. GlobeCore design department developed a unique technology implemented in the UVR units. It cleans andRead More

Individual Approach to Oil RecoveryTransformer oil – is a main isolator in transformer. In addition, it serves as a coolant. It entirely stabilizes electrical breakdown of transformer. However, its indispensability is dangerous – transformer oil is influenced by moisture and temperature, dissolved gases and various harmful particles that are accumulated in the process of aging. The oil also reactsRead More

Desulfurization of Diesel Fuels

Desulfurization of Diesel Fuels The chemical composition of any oil product is a mix of different elements. Here you have hydrocarbons, hydrogen, oxygen with nitrogen, and sulfur. It is clear that the presence of these and other elements is defined by the type of feedstock (petroleum oil), and the method of oil process. To produce diesel fuel, good forRead More

Guests from Bulgaria visited GlobeCore office in OldenburgJune 1, 2016, GlobeCore head office held a regular presentation of our products. This time Bulgarian specialists attended GlobeCore’s presentation of the oil processing technology and maintenance of power transformers. GlobeCore lead engineer introduced the company’s history and the capabilities of equipment for: Filtration of mineral oils; Degassing of mineral oils; Regeneration of mineral oils;Read More

A Business Trip to Namibia

A Business Trip to Namibia June 1-2, GlobeCore employees visited Windhoek (Namibia) to hold several meetings with the representatives of the Namibian electricity sector. During these meetings, GlobeCore presented its units for filtration, vacuum degassing and regeneration of mineral oils and equipment designed for air-drying transformer solid insulation. The UVR regeneration unit caused particular interest. This equipment uses a uniqueRead More

Ecuador. Startup of CMM-12R plant in Andean highlands

Ecuador. Startup of CMM-12R plant in Andean highlands August 25, Ecuador (in. Quito) GlobeCore engineers commissioned the CMM-12R plant. The test run of the unit achieved outstanding dielectric loss tangent of 0.7% at 90°C (with initial value – 11%), it also increased breakdown voltage to 80 kV. Note that the CMM-12R plant has the following advantages: Round the clock reclamation of transformer oilRead More

A business opportunity: purification of contaminated diesel fuel

A business opportunity: purification of contaminated diesel fuel Owning a business is a way of being self-sufficient and independent, and allows a degree of confidence in tomorrow. However, not all try to start a business, the reasons numerous: lack of starting capital, the risks involve, lack of knowledge in the field and many more. First complications arise at the stage of finding aRead More

Mineral Oil Processing EquipmentOxidation, contamination and other impurities accumulate in oil during operation, drastically reducing its quality. Oil processing equipment restores the original properties of oil, substantially reduces oxidation products and water – for oil to be reused for its intended purpose. The simple regeneration processes include: sedimentation and filtration; sedimentation, adsorptive purification and filtration; sedimentation, alkali treatment,Read More

Waste Oil Recycling Methods. Oil refining plant GlobeCoreAnnually tens of thousands of tons of waste synthetic and mineral oils are accumulated on the territories of each industrialized country. They are highly toxic, they have low level of biodegradability (10-30%) and by accumulating in the environment they disturb an ecological balance. Existing regulations require mandatory collecting and recycling of waste oils and inRead More

Used Oil Refinery UnitDifferent types of oil are used in various industries. And the more machinery use oil, the bigger is the problem of waste oil – its refinery or disposal. After its purification from mechanical and other impurities which accumulate during its operation – the oil can be used more than once. According to the degree ofRead More

Transformer Oil Purification

Transformer Oil Purification The application of oil is very wide. It is used in transformers, oil circuit breakers, high-voltage capacitors and power cables. Oil in transformers – provides insulation, reduces heat, also fills the tank in oil circuit breakers. Continuous development of electrical engineering sets higher requirements to the purity of transformer oil. Experts agree that – serviceRead More

A seminar on mineral oils purification and regeneration in OldenburgApril, 21-22, 2016 the German GlobeCore office (Oldenburg) held a seminar on purification and regeneration of mineral oils. This event was attended by the representatives of Belgium, the UK and the Czech Republic. Let us remind you that GlobeCore Oldenburg operates a successful International Training Center, where anyone can take a course in using theRead More

The new CMM-RP sorbent reactivation unit

The new CMM-RP sorbent reactivation unit In the first quarter of 2016, GlobeCore completed the project of developing and manufacturing of the new CMM-4RP waste sorbent reactivation unit. This product us designed for restoration of waste bleaching earth sorbents, used industrially for purification of oils, heavy fuel, diesel and other petrochemical products. The waste sorbent is loaded into invertible columns ofRead More

Middle East Electricity, 1-3 March 2016, DubaiDear colleagues, feel free to visit us at Dudai World Trade Centre, UAE We will present GlobeCore Oil Processing Equipment at Middle East Electricity – The World’s Largest Power Event Visit us at Dubai World Trade Centre, UAE 1-3 March 2016, Stand No. S2E69, Sheikh Saeed Hall No. 2 Open daily 10 am – 6Read More

How to Remove Water and Mechanical Impurities from Diesel Fuel?The Contamination Process of oil products traces its roots to oil refineries and accelerates at each subsequent stage of the petroleum’s life cycle. The concentration of pollutants in an automobile fuel tank can reach up to between 0.04 to 0.06 g/kg (for gasoline) and 0.15 to 0.6 g/kg (for diesel fuel). It is also nearlyRead More

The Vortex Layer Device (magnetic mill)

The Vortex Layer Device (magnetic mill) The new GlobeCore Vortex Layer machine currently has quite a large amount of uses. The casing 1 is made of nonmagnetic material and has the form of a hollow cylinder. It is placed into the work-coil 2, which creates a rotating electromagnetic field. The work-coil is placed into the metallic jacket 3, to protect personnelRead More

Atmospheric air drier ‘Mohave Heat’ commissioned in Oman

Atmospheric air drier ‘Mohave Heat’ commissioned in Oman On 17 December commissioning of an automated Mohave Heat air drying unit was completed in Oman. This product is designed to dry atmospheric air to dew point of -50… -70ºС and to remove dust and particles. The unit is used while installing or repairing transformers. Some of the applications are: opening transformers draining oil fromRead More

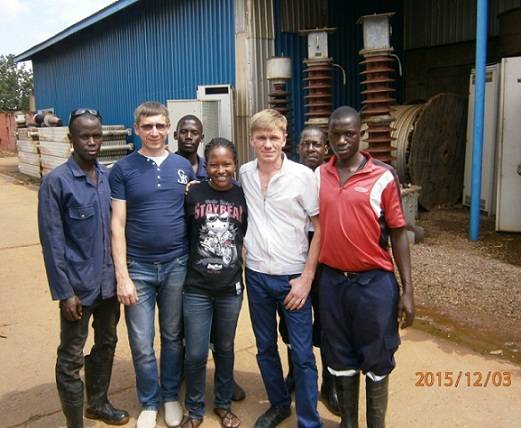

Successful commissioning in Uganda

Successful commissioning in Uganda On 3 December 2015, GlobeCore specialists successfully commissioned a CMM-4D unit in Uganda. This unit employs heat and vacuum to purify electrical insulation oils. The oil is finely dispersed in the vacuum chamber, where special activator filters increase the surface area of treatment. СММ-4D units can: purify transformer oil, removing particulate matter, water and gas;Read More

Removal of Heavy Metals from Wastewater Generated at Electroplating Workshops

Removal of Heavy Metals from Wastewater Generated at Electroplating Workshops We discuss Electroplating Wastewater Treatment in this article. At the beginning of the twenty first century, the urgency of solving the issues of global environmental problems significantly increased. Today, humanity has almost come to the point where further ignoring of the need to preserve the Earth’s ecosystem will be very costly for future generations. ThereRead More

Grinding of Coal to a Pulverized State

Grinding of Coal to a Pulverized State Today, a significant amount of the energy generated and consumed around the world is produced by burning fossil fuels. In addition to oil and natural gas, coal is also quite actively used as an energy source. At modern electric power plants, solid fuels are ground into a pulverized state and, in an admixture with air,Read More

Reagent Automatic Dosers for Wastewater Treatment Systems That Operate Using Vortex Layer Devices

Reagent Automatic Dosers for Wastewater Treatment Systems That Operate Using Vortex Layer Devices GlobeCore designs, manufactures, and installs wastewater treatment systems that utilize vortex layer devices. The main feature of these machines is the complex effect the devices have on processed materials. The processing consists of intensive mixing and dispersion, acoustic and electromagnetic treatment, friction, local pressure, and electrolysis. The GlobeCore Process of using the vortex layer devicesRead More

Design, Manufacture and Installation of Wastewater Treatment Systems on the Basis of Vortex Layer Devices

Design, Manufacture and Installation of Wastewater Treatment Systems on the Basis of Vortex Layer Devices Each year the world produces about one trillion cubic meters of wastewater. Approximately one fifth of which receives no treatment before being discharged back into water sources. The greatest threat to the world’s water supply is posed by industrial effluents resulting from activities in the chemical, food, machine-building, instrument-making, petrochemical, and radiochemical industries. Wastewater dischargedRead More

Automatic Loading of the Grinding particles in the Working Chamber of the Vortex Layer Device

Automatic Loading of the Grinding particles in the Working Chamber of the Vortex Layer Device Electromagnetic devices with a vortex layer of ferromagnetic particles were first proposed in the 1960s. In these devices, complex interactions take place between ferromagnetic particles, fluids and materials that are being processed. This speeds up the process of mixing and grinding. Moreover, the vortex layer devices can successfully be used as reactors. GlobeCore manufactures theRead More

Application of Vortex Layer Devices for Improving the Quality of Marine Fuels

Application of Vortex Layer Devices for Improving the Quality of Marine Fuels The first time the possible use of water, in the feed system of internal combustion engines was discussed, took place in the late nineteenth century. Since then, there have been many studies on the effectiveness of the approach of adding water to fuels. A couple of known benefits to adding water to fuels include: intensifiesRead More

GlobeCore’s Magnetic Metal Traps for the Food Industry

GlobeCore’s Magnetic Metal Traps for the Food Industry One of the many possible applications of GlobeCore’s vortex layer devices is the processing of the liquid-phase found in heterogeneous systems. GlobeCore’s Vortex Layer device is designed to intensify technological processes in various industries that include the food industry, chemical industry, and the microbiology industry. The principle of operation of a vortex layer device isRead More

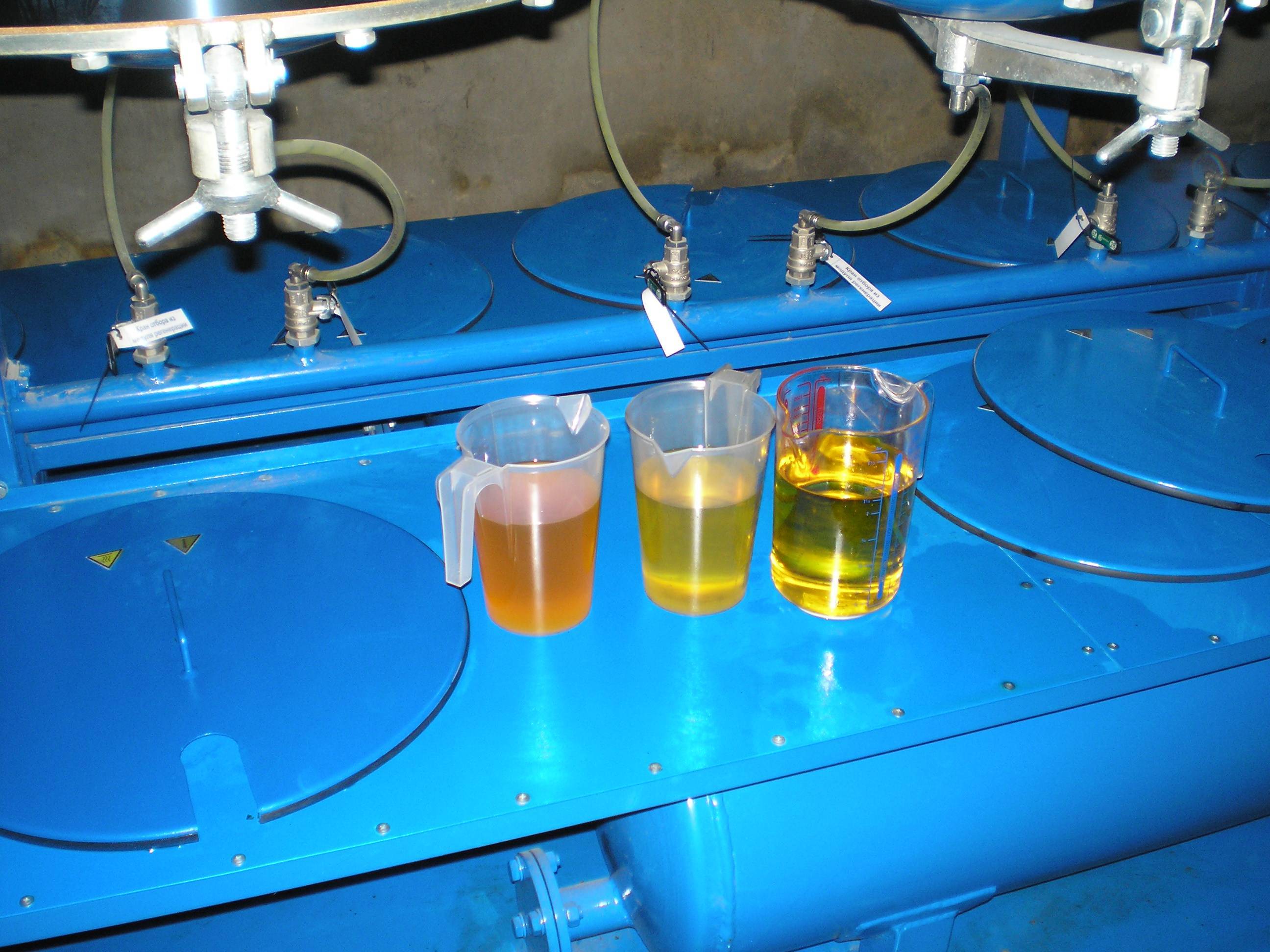

Presentations of GlobeCore Oil Purification Equipment held in Azerbaijan

Presentations of GlobeCore Oil Purification Equipment held in Azerbaijan From 12 October to 16 October 2015, a delegation from GlobeCore paid a working visit to Azerbaijan. GlobeCore’s representatives visited Baku and Ganja where they made four presentations and a demonstration of GlobeCore’s UVR-L type laboratory unit. The power supply specialists who were in attendance at the presentation were shown in detail the different linesRead More

Discussing the Issues to Expand the Areas of Application for Vortex Layer Machine

Discussing the Issues to Expand the Areas of Application for Vortex Layer Machine In February, the associate professors of the Dapartment of technological equipment for food production and trade of Poltava University of Economics and Trade, Mikhail Ivanovich Nikitenko and Vasiliy Nikolaevich Oberemko, delivered a joint lecture to the GlobeCore staff. Both of them have a great experience working with the Vortex Layer Machine therefore, the lecture wasRead More

Diesel Oil Purification: Modern approachesGlobeCore units are designed to purify, lighten, regenerate and remove aromatics from all types of diesel fuel and restoring it to a marketable condition and restoring its original performance characteristics. Diesel fuel is acknowledged to be one of the most marketable oil products today due to such advantages as: (1) relatively low price; and (2)Read More

What to Do With Used Oil?First, we must understand what the term “used oil” means. We suggest using the definition given by the United States Environmental Protection Agency (EPA). It says that, “used oil is any oil that has been obtained from crude or synthetic oil that has been in use and as a result was contaminated by physical andRead More

The Reasons for Diesel Oil Contamination and the Methods of its PurificationThere are two main problems facing the owners and operators of diesel fueled equipment; (1) diesel fuel loss and (2) degradation of the equipment’s performance characteristics. Both problems will lead to increased costs and lowered efficiency. All oil product contamination may be divided into the followoing groups: (1) organic (fuel oxidation products) and (2) non-organicRead More

Anhydrite Binder Production by the Vortex Layer MachineIntroduction Today’s modern alabaster industry produces products based on alabaster binding materials. Such products are obtained by burning natural material at low temperatures to obtain hemihydrate of calcium sulfate. It is worth noting that fired and non-fired alabaster binders are rarely used in this process. This is due to the fact that such binders needRead More

Vegetable Oil Hydration: What Equipment to Choose?

Vegetable Oil Hydration: What Equipment to Choose? Vegetable oil hydration consists in removing the phospholipids from the raw product. These lipids are of high biological value. The amount of the phospholipids in the vegetable oil ranges from 0.2 tо 4.5% and depends on the kind of the raw material and the way the vegetable oil is obtained. When the product is firstRead More

The “Vortex Layer” Machine: Patent SearchThe “Vortex Layer” Machine AVS-100 can be used in the chemical and power industries. Additionally, this machine is designed to purify industrial and household waste water. The “Vortex Layer” machine consists of a working chamber (pipeline) with a diameter that ranges from 60 to 330 mm (millimeter). This working chamber is arranged in the inductorRead More

The Sulphur Process Intensification in the Vortex Layer UnitSulphur is one of the most widely used chemical elements inthe industrialized world. In the petrochemical industry, sulphur is considered to be a waste product and needs to be recycled. There has been no optimal solution for the recycling of sulphur for a long period of time. But, in the 1970s in the USA andRead More

Pre-Sowing Treatment of Grain by the “Vortex Layer” MachineThe quality of the grain seeds can be defined by some external factors as well as by its biological characteristics. It is very difficult to control all the factors that affect the grain seed during its time of germination. But there is however, a defined set of methods in the agriculture industry that reduce theRead More

Sunflower Oil Dewaxing by ‘Vortex Layer’ system

Sunflower Oil Dewaxing by ‘Vortex Layer’ system Vegetable oils and fats are mainly defined by their physical, chemical, electrophysical, and electromagnetic characteristics. Nowadays, sunflower oil dewaxing, affected by the electric or electromagnetic field, is considered to be very effective. The electrophysical effect on organic substances and materials is considered to be a relatively new approach which was first introduced in the 1960s. Read More

Desulfurization as a Method of Oil Decoloration

Desulfurization as a Method of Oil Decoloration Harmful emissions that are discharged into the atmosphere are increased when burning high sulfur content diesel fuel. It is therefore, why great efforts are focused on removing this chemical element from Diesel fuels. Additionally, the desulfurization of Diesel fuel allows indsutries to: (1) prevent sulfuric acid corrosion of boiler equipment; (2) re-direct sulphur so thatRead More

Decoloration of Black Oil

Decoloration of Black Oil The state of today’s environment has become greatly affected by the amount of emissions and harmful substances coming from internal combustion engines. Such engines are used in the transportation industry as well as at stationary power plants. The progress in the field of engine building has recently served to reduce the amount of harmful dischargesRead More

Fuel and Oil DecolorationA fuel and oil decoloration process is needed to reinstate oil products to marketable condition. Different contaminants have a great impact on the natural colour of oil products. These contaminnants can get into the oil during transportation or storage as well as during operation. In many cases it is the colour that allows you toRead More

Practical Guides for Drivers: How to Save FuelThere are many practical ways to increase the efficiency of your car and conserve fuel. Nowadays, fuel conservation has gained significance because of the high prices of gasoline and Diesel fuel. Fuel conservation benefits not only the owner, but the car as well since using the car more efficiently will also bring the owner aRead More

GlobeCore sets course for East Africa. Uganda Electricity Transmission Company Limited and GlobeCore – a new partnership

GlobeCore sets course for East Africa. Uganda Electricity Transmission Company Limited and GlobeCore – a new partnership GlobeCore is a leading manufacturer of various equipment, such as transformer oil purification and regeneration plants, bitumen emulsion plants, bitumen modification plants, fuel blending systems and bio-diesel production system, employing over 200 staff on the production team. Our products are well known in the USA, Europe, Asia and Africa. While we are open to businessRead More

Fuller’s earth for industrial oil regenerationThe one of the most used petrochemical products on production facilities is industrial oil and different types of this oil. Industrial oil is the most available and reliable for liquid insulation, for cooling and electrical protection for power transformers, turbines, hydraulic equipments etc. Industrial oil has a lot of advantages which include long lifetime (withoutRead More

Turn the waste into profits. Waste oil recycling machine.Waste oil recycling machine One of the aspects of successful development of each business is implementation of innovations. We all are searching every day new resources to obtain more profits. There exist the materials which can be used again and again but because of shortage of equipment or knowledge we cannot use it on 100%.Read More

Difference between Oil Purification and Oil RegenerationGlobeCore’s Oil Regeneration (Reclamation) Units are “Two-in-One” industrial systems that not only Purify used and/or contaminated oil, but completely Regenerate/Reclaim the used oil and restore used oil to its original new condition. This new, industry leading technology was designed by GlobeCore’s engineers and the UVR units can perform oil and fuel regeneration/reclamation at a fraction ofRead More

Latex and rubber production: application of AVSThe bottlenecks in production of rubber and latex articles are long desintegration and mixing time, difficulty of uniform distribution of extenders and other ingredients into the caoutchouc and latex, long vulcanization time. To activate particle surface of extender (for example, soot) it can be exposed to the grinding by ball or vibrating mills. But thisRead More

Wastewater treatment from fluorine and nitrocompoundFluorine-containing wastewater The wastewater from chemical and metallurgical enterprises which contain fluorine compounds is classified as harmful wastewater. Treatment of these wastewater from fluorine involves some problems and requires of considerable expenses and expensive reagents. Water treatment from slight fluorine concentration is extremely important. These difficulties are concerned with chemical particularities of fluorine compounds. AsRead More